With the rapid development of industrial automation and intelligent manufacturing, industrial intelligent gateway plays an increasingly important role in the field of industrial automation as an important hub connecting different devices and systems.Modbus protocol, as a communication protocol widely used in the field of industrial automation, has the characteristics of simplicity, reliability, openness, etc., and it is widely used in the communication between various industrial devices and systems.

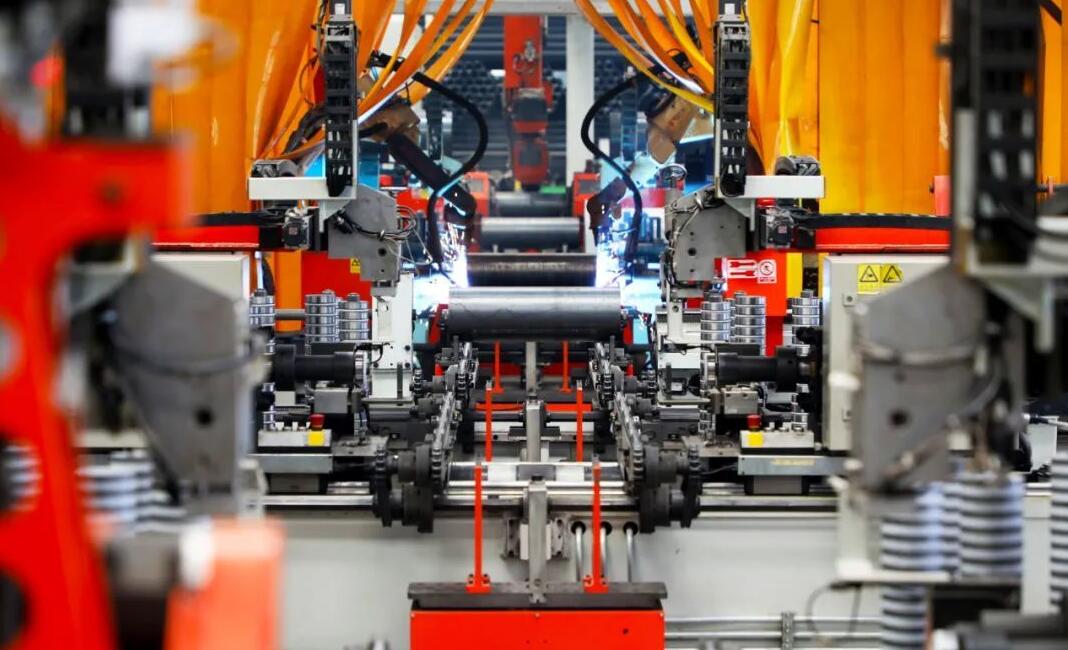

The industrial intelligent gateway launched by IOTROUTER has the ability to collect data from PLCs, sensors, instruments, industrial robots, CNC machine tools and other Modbus devices, and connect to cloud platforms or host computers through 5G/4G/WIFI/Ethernet, etc. The upstream protocol supports Modbus/MQTT and other protocols, so as to realise a variety of functions, such as data collection, remote monitoring, and edge computing. The uplink protocol supports Modbus/MQTT and other protocols, so as to achieve data collection, remote monitoring, edge computing and other functions.

Application of industrial intelligent gateway in Modbus protocol transmission

Device Interconnection Communication: Industrial intelligent gateway as a communication hub effectively connects different devices using Modbus protocol, enabling smooth exchange of data and control commands between them. This interconnectivity promotes the construction of industrial automation systems and creates conditions for collaborative work and data interoperability between devices.

Remote Monitoring And Maintenance Innovation: Industrial intelligent gateway supports remote access, providing engineers with the means to remotely monitor and maintain Modbus devices. Engineers can view the Modbus register content of PLC devices in real time, quickly obtain the real-time status of the equipment and potential problems, so as to carry out timely troubleshooting and maintenance, ensuring the continuous and stable operation of the equipment.

Data Acquisition And Intelligent Processing: Industrial Intelligent Gateway is not only capable of data acquisition for Modbus devices, but also has the ability of data processing. By accessing the Modbus interface with the equipment, the gateway can capture the operating data and status information of the equipment in real time, and further transmit these data to the host computer or data centre for in-depth analysis and processing, providing powerful data support for production monitoring and decision-making.

Advantages of industrial intelligent gateway in Modbus protocol transmission

Excellent Stability: The gateway is tailor-made for harsh industrial environments, it has excellent high performance and stability, thus ensuring the stability and reliability of the Modbus protocol in the transmission process, providing a solid guarantee for the continuous operation of industrial automation systems.

Wide Compatibility: The gateway supports a wide range of protocols and different transmission methods, such as RTU and TCP, and pairs to cloud platforms or host computers via 5G/4G/WIFI/Ethernet. This broad compatibility enables it to adapt to the communication needs of various devices and systems, bringing great convenience to industrial automation.

Robust Security Protection: Considering the importance of data in industrial automation systems, the Industrial Smart Gateway is equipped with firewalls, whitelisting and other security protection features. Together, these features ensure the security of Modbus protocol transmission, effectively preventing the risk of data leakage and unauthorised access to devices.

Outstanding Expandability: With the continuous development of industrial automation system, higher requirements are put forward for the expandability of equipment. With its flexible interfaces and powerful expandability, the Industrial Smart Gateway can easily integrate and expand with other devices and systems, providing strong support for the future development of industrial automation systems.